Businesses across multiple industries, including manufacturers, distributors, commercial facilities, and research institutions, often need to dispose of potentially hazardous or inhibitory materials through the various wastewater streams, requiring proper assessment and treatment. To ensure proper compliance with regulatory requirements, the client must first establish a safe concentration and rate of disposal. RespirTek specializes in wastewater treatability studies, focusing on site-specific testing protocols utilizing the appropriate combination of respirometry, microbiological testing, and biological and chemical analyses.

This case study details the wastewater treatability testing that RespirTek recently completed for a client. A product manufacturer produced a large volume of process wastewater which required discharge through the local municipal wastewater treatment plant (WWTP) and needed to identify the risk of inhibition by the waste stream within the wastewater treatment process.

The client supplied a sample of the waste stream containing the contaminant of concern (COC), along with a sample of the influent wastewater inoculum from the WWTP where the waste stream would be discharged. The impact of the COC on the waste stream was evaluated using microbial enumeration, which was carried out in accordance with Standard Methods for the Examination of Water and Wastewater method 9215 B. Sets of serial dilutions were completed using the inoculum, which were then plated with standard agar and incubated at 35 °C. Microbial colonies were enumerated at 48 hours following the guidance set forth in SM 9215. Specific degrader (SD) plate counts were prepared and enumerated identically, with the exception of a 1 mL addition of stock solution containing the COC being applied to the inoculated agar. The Standard Methods 9215 protocol requires sterility controls to be prepared; thus, the following controls were also performed: a negative control containing only agar (for each flask of agar used), a positive control in which 1 mL of aerobic microbial mix was added, a dilution water control, and an air control (a plate left open for 15 minutes).

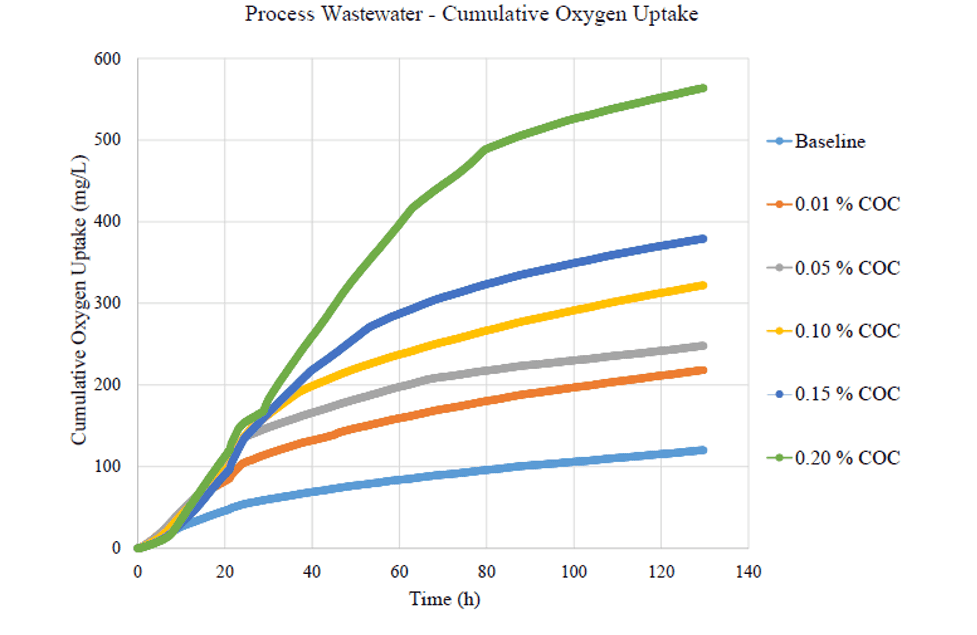

Oxygen uptake was measured by a PF-8000 Respirometer System capable of reading incremental respiration values of less than 0.1 mg O2 via pressure transduction. Ten 500 mL reactors were prepared to evaluate the impact of the COC at five different concentrations, which were indicated by the client, as well as two baseline control reactors. Each reactor was monitored for cumulative oxygen uptake. The reactors were prepared by introducing increasing concentrations of the COC in accordance with the following matrix:

Rx 1A & 1B: Inoculum + Influent (Baseline)

Rx 2A & 2B: Inoculum + Influent + 0.01 % COC

Rx 3A & 3B: Inoculum + Influent + 0.05 % COC

Rx 4A & 4B: Inoculum + Influent + 0.10 % COC

Rx 5A & 5B: Inoculum + Influent + 0.15 % COC

Rx 6A & 6B: Inoculum + Influent + 0.20 % COC

The microbial enumeration results indicated that growth on plates containing the COC was comparable to that on plates without contaminants, demonstrating no inhibitory effects. Respirometry data showed a rapid response to the introduction of process wastewater shown in Figure 1., with cumulative oxygen uptake increasing alongside higher COC concentrations in each reactor set. Collectively, these findings confirm that the inoculum effectively degraded the organic components of the influent over 135 hours of incubation, with no significant inhibition under the tested conditions.